Jim Bauer Enterprises

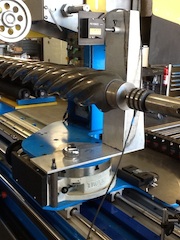

• Rotor Polishing Lathes •

• Engineered for reliability •

Jim Bauer Enterprises Produces

World Class Polishing Lathes For The Oil Field Industry.

Our Rotor Polishing Lathes Are Currently Used in 5 Countries

• Power Section Rotors

• Progressive Cavity Pumps

• HVOF Rotor Spray Lathes

• Laser Measurement Systems

Our machines resurface and polish rotors to specifications that match wellbore conditions to maximize rotor fit, torque and efficiency.

Rotor Polishing

- HVOF Rotor Polishing

- Chromed Rotor Polishing

- Milling Machine Tool Mark Removal

- Single Lobe Rotors

Our engineering team works every project from a custom design perspective whether the client requires standard off-the-shelf components or a unique solution.

Components

Components

- All Alan Bradley Control Systems

- 3 Axis CNC Control Systems

- Panelview HMI Interface

- Custom Programming

- Bed Lengths to 10 meters (40 feet)

- Travel Vent Dust Collection Systems

- Multiple Steady Rest

- Both Belt & Wheel Polishing

- HVOF Coolant Systems

below are Typical Jim Bauer

Manufacturing Lathe Specifications

Unequaled engineering

& manufacturing

- 3- Axis CNC Control

- 1- Axis Manual Indexing

- Custom Programming for Both

Singlelobe and Multilobe Rotors - Bed Lengths up to Forty Feet

- All Alan Bradley Control Systems

- Control Logix PLC

- Alan Bradley Servo Motors and Drives

- Panelview HMI Interface

- HVOF Water Coolant System

- Variable Speed Polishing Head

- 0 to 6500 feet/min Belt Speed

- 1 inch to 4 inch X 120 inch belts

- 3 Horsepower Polishing Head

- Built in Overhead Fluorescent Lighting

- Travel Vent Dust Collector System

- Torit or Farr Dust Collector

- Multiple Steady Rest on Slide Rails

- 24 in and 36 inch Steady Rest Rollers

The Jim Bauer manufacturing team works hand-in-hand with the engineering team to produce components and machines to exacting standards for all rotor grinding and polishing lathes. Components are engineered to withstand harsh job site conditions as well as handle the stresses of crating, loading, shipping, unloading and installation. We’re experts at assembling or manufacturing the right components for each job and putting it all together to provide each customer with an individualized machine to meet their specifications.

Jim Bauer Enterprises

Manufacturing Engineering Services

Fairfield, California (USA)

(707) 689-8040